Finding Your Prints Charming

When it comes to custom sports and teamwear, adding colour and pattern is a bit like picking the perfect song – different styles work for different moments. Two of the most common methods are screen printing and sublimation. They work in very different ways, and each has its place: screen printing is a popular option for high-volume finisher T-shirts and event kit, while sublimation is the go-to for fully bespoke teamwear. This guide explains how they both work, their pros and cons, and when each is typically used.

What’s the Difference Between Screen Printing and Sublimation?

Think of screen printing like a long-lasting but ultimately temporary tattoo. It sits on the surface of the fabric; you can usually feel it, and it’s likely to crack, peel, or fade over time, especially with a lot of wear, stretching, or washing.

Sublimation is more like a permanent (but pain-free) tattoo. The colour is embedded deeper into the fabric, making it permanent. You can see it but can’t feel it, and it won’t peel off over time.

What is Screen Printing?

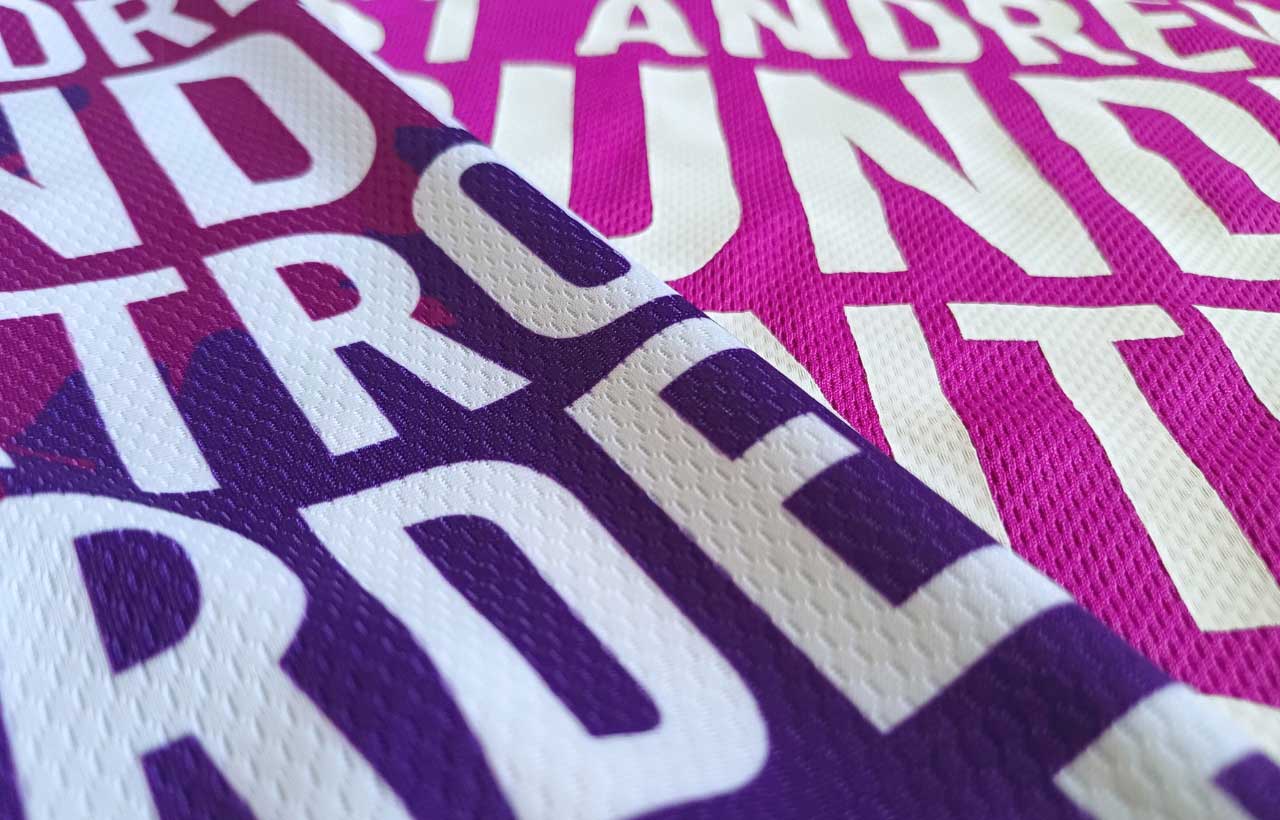

If you tried screen printing at school, you’ll remember pulling a rubber squeegee across a mesh panel to push ink through a stencil. In garment production, the process works the same way – ink is pressed through a screen onto fabric. Just as in art class, each colour needs a separate screen, which pushes up initial set-up costs but makes screen printing a cost-effective choice for larger orders because these screens can be used time and time again. It’s versatile and works on most fabrics, including cotton and polyester, though it’s got limitations on the amount of detail it can offer.

The final effect depends on the type of ink used. Plastisol inks (see below) create a layer that sits heavily on the fabric, while water-based inks soak in more lightly, giving a softer, thinner feel. In both cases, the print sits on or near the surface of the fabric.

Screen printing doesn’t lend itself to personalisation because each name or number would need its own screen. Instead, they’re usually added afterwards as a separate process using heat-press vinyl.

Plastisol Inks

Advantages:

- Vibrant, strong colours – great for logos and bold branding

- Works well on most fabrics, including cotton and polyester

- Want a bright design on a dark fabric? Plastisol’s the way to go

Disadvantages:

- Can feel heavier on the fabric

- May crack or peel over time with stretching or heavy washing

- The plastic-type coating can reduce fabric breathability

Water-Based Inks

Water-based inks soak slightly into the fibres rather than sitting purely on top, creating a lighter, more natural finish. They’re often chosen when a softer look and feel is preferred.

Advantages:

- Lightweight finish with almost no “ink layer”

- Keeps fabric breathable, ideal for activewear.

- Can create a softer, vintage-style look compared with plastisol.

Disadvantages:

- Colours can be less vibrant, especially on dark base fabrics.

- The print can fade faster than plastisol prints.

What is Sublimation?

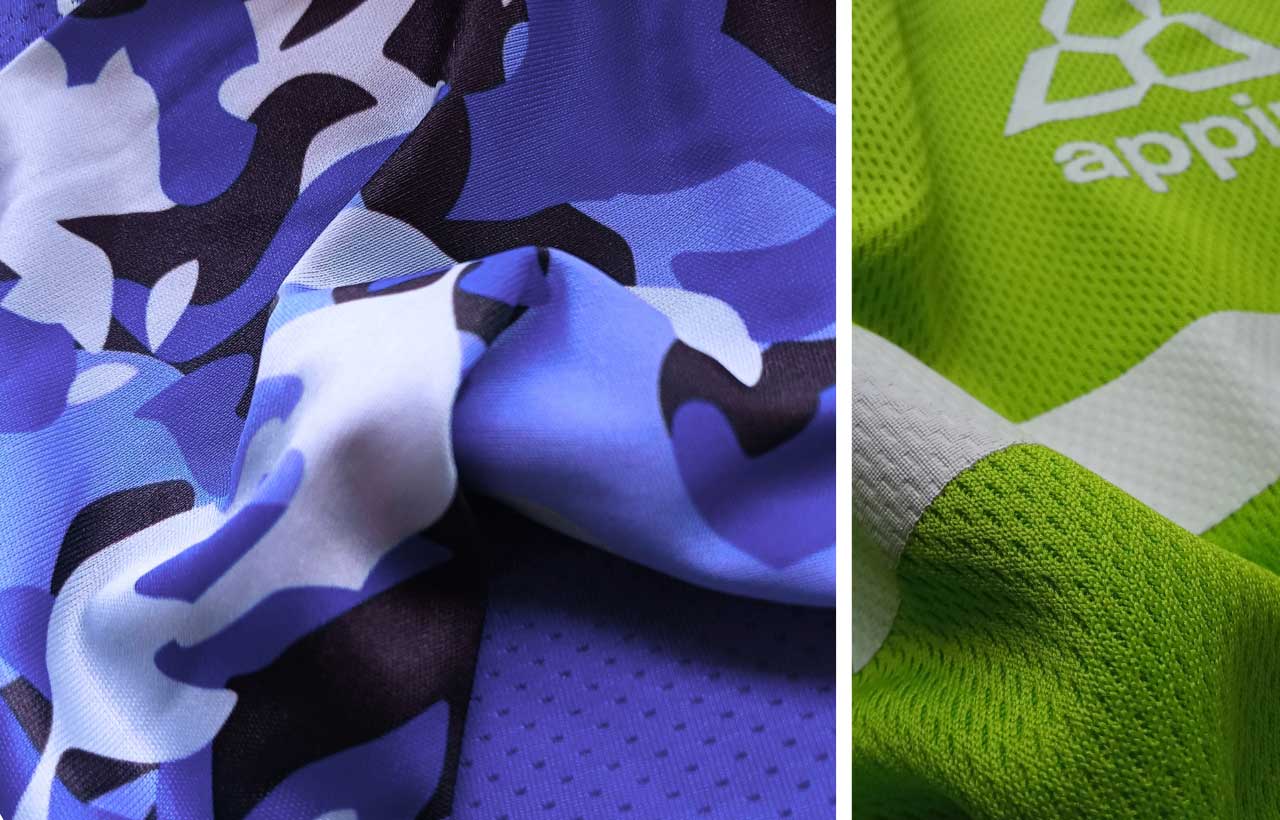

Sublimation printing transfers a design from special paper onto fabric using heat and pressure. The ink turns into gas and bonds with the fibres, becoming part of the material itself. Best for detailed designs and all-over prints, sublimation only works on white or light-coloured polyester fabrics.

Advantages:

- Unlimited colour options, gradients and intricate detail.

- Invisible to the touch with no impact on breathability.

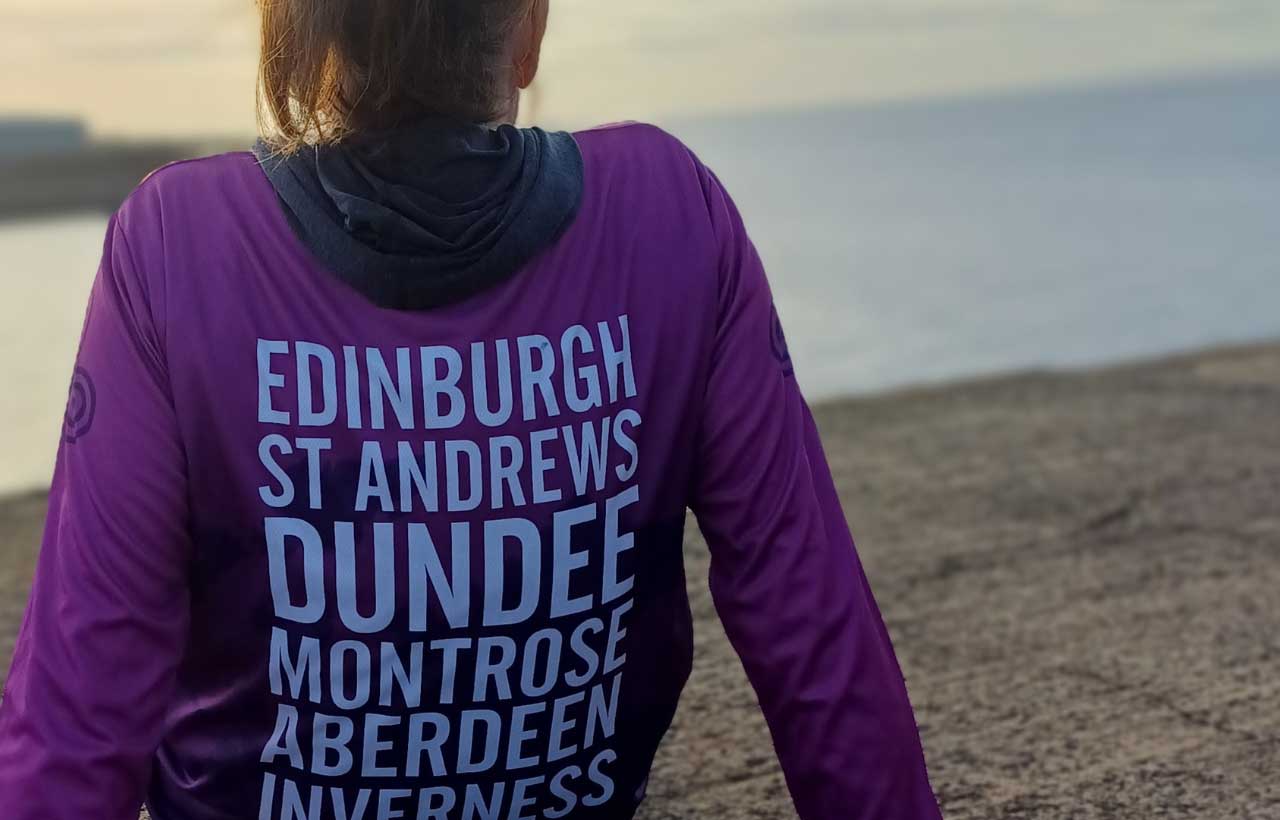

- Easy to personalise – names, numbers and small design changes can be added with no extra set-up cost.

- Digital files make reprints simple and consistent; no need to keep bulky screens.

Disadvantages:

- Works best on polyester; cotton requires a special coating that reduces breathability and durability.

- More expensive than screen printing for large volumes.

- Not suitable for dark fabrics — colours won’t show clearly.

What Makes Our Sublimation Different?

Many suppliers sublimate or screen print onto ready-made garments, which limits where and how big the design can be.

At Appin Sports, we do things differently. We start from scratch and print the fabric first, then make the garment. That means you can have true all-over designs – top to bottom, side to side – whether screen printed or sublimated.

Which Should You Choose?

Choosing between screen printing and sublimation depends on your needs.

- Screen printing – best for bold designs and large orders.

- Sublimation – ideal for lots of detail, pattern or colour, smaller volumes, or personalised teamwear.

Crossing the finish line

Screen printing and sublimation both deserve a place on the podium. For us, screen printing is the go-to for event tees, while sublimation makes fully custom teamwear possible – all-over designs, edge to edge, with personal touches like names and numbers.

One thing never changes though: the kit has to be good enough that we’d wear it ourselves. That’s the standard we work to, and the reason we’re proud to put our Appin Sports name to it.

Find out more about custom kit

Got a project in mind? Contact our team – we’ll help you create kit that looks great and works for your club, charity, or event.